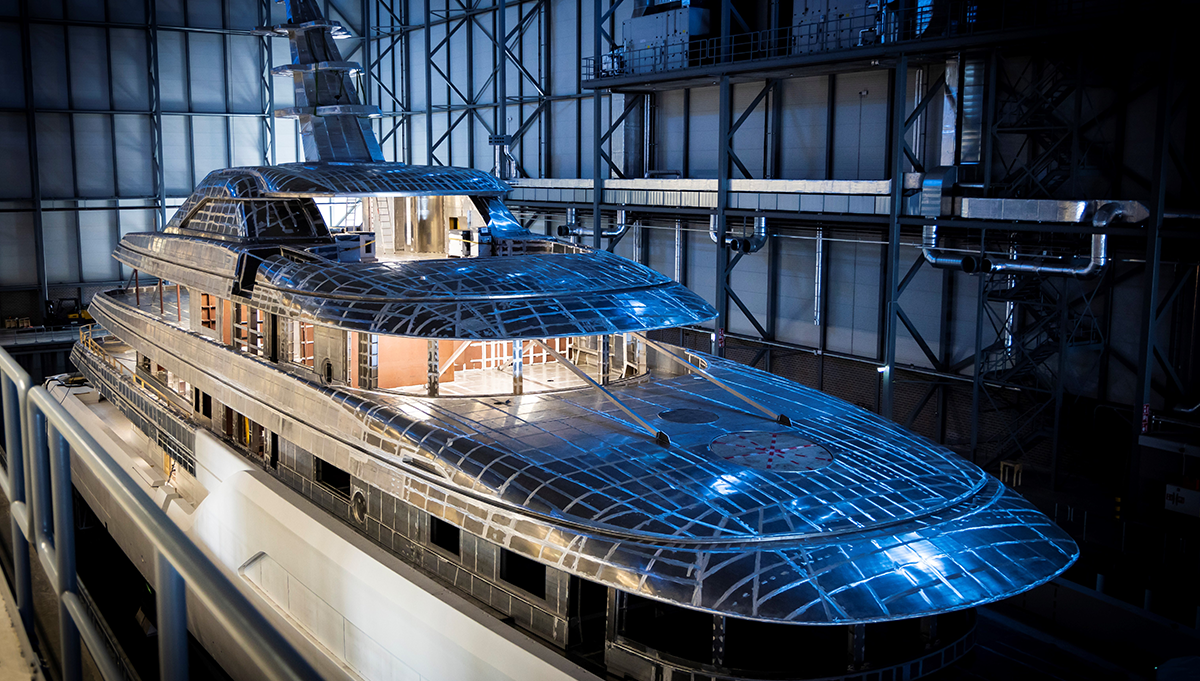

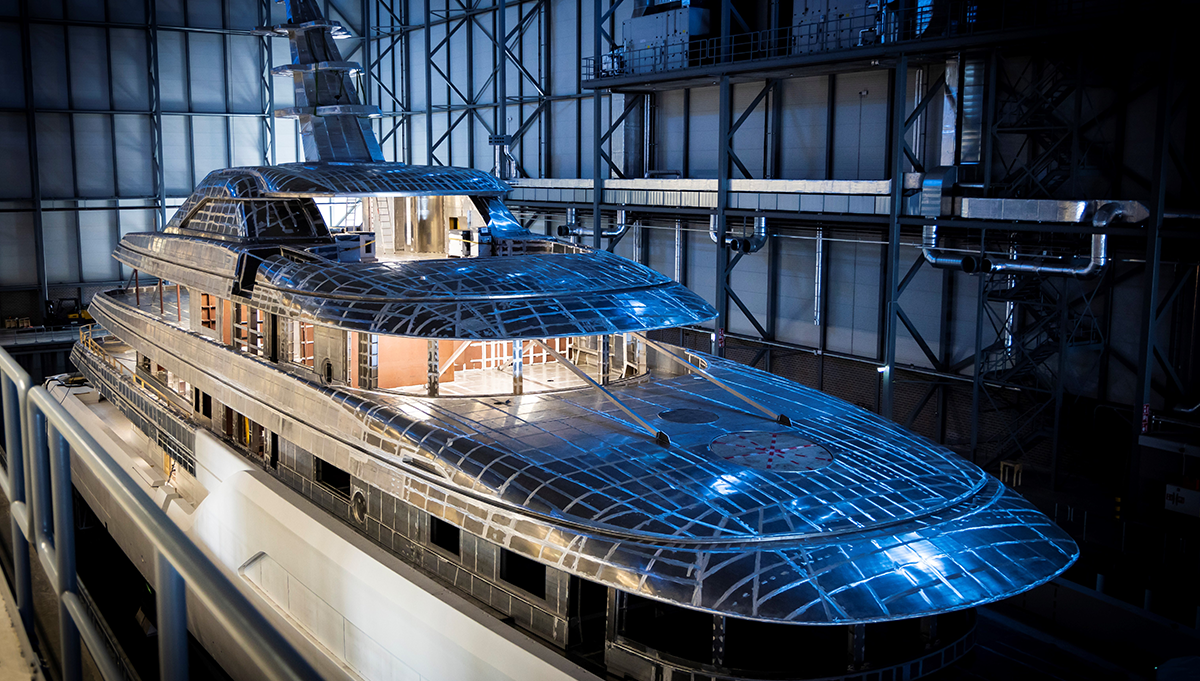

Construction at CRN

Construction at CRN

The superyacht test bed

The superyacht industry isn’t just proactively looking to reduce or eliminate its own vessel emissions, it is actually serving as the technological testing ground for the wider maritime sector – and that could be hugely important in our battle against climate change.

As the responsibilities of humans toward the health of the planet take ever more the centre stage, and as calls to action to make changes in our industrial processes get ever louder, it feels increasingly like the superyacht industry is nearing a defining moment. That moment, however, is not that yachts are becoming indefensible, but rather that they are at the forefront of change, and driving the marine energy transition. In doing so, superyachting is proving to the vastly larger (and more climate-impacting) commercial maritime sectors that new technologies not only promise a cleaner future but that they actually work.

There are numerous examples stretching back over the past 20 years or more of innovative yachts that have taken steps forward in efficiency and in the adoption of emission-reducing technologies and hybrid powertrains that allow for zero-emission modes. But three projects in build and nearing completion at three different shipyards – Lürssen, Feadship and Sanlorenzo – are pushing boundaries by making the leap into completely new fuels.

Lürssen Photo: Klaus Jordan

Lürssen Photo: Klaus Jordan

Take the Lürssen project currently known as Cosmos, for example. The 114.1-metre yacht will feature fuel cells instead of a hybrid battery bank, fed by reformed methanol, and it draws on extensive research that the yard has been conducting into the tech. “We have had a test bank running for a year already,” states Michael Breman, Sales Director at Lürssen Yachts. “As a result we have installed one megawatt of fuel cells in Cosmos that will allow the boat to do 1,000 miles purely in [electric zero emission] fuel cell mode, or will be able to achieve two-and-a-half weeks in what we call zero emission mode at night, running all the domestic systems off the fuel cells with no generators running.”

This is a real project for a real client, with a real launch and delivery date, and it’s the same with other groundbreaking yachts. “In the first half of next year we are delivering a 118-metre hydrogen variant of what Lürssen is doing,” confirms Farouk Nefzi, Chief Marketing Officer at Feadship, who also points out that moving an industry forward doesn’t necessarily need such big leaps. “We just delivered an 84-metre yacht called Obsidian,” he continues, “and that yacht features an emission reduction of 90 percent over a conventional diesel-powered vessel, not going crazy with future technology but just by making the engines compatible with HVO (hydrotreated vegetable oil) renewable diesel. It’s a hybrid solution that’s already there. As an industry, we are adapting and we are challenging ourselves.”

Feadship

Feadship

At Sanlorenzo, where a 50-metre yacht that features fuel cells is nearing completion and is due for launch in 2024, the team are celebrating receiving approval from the classification society Lloyd’s Register for its methanol fuel cell system and type-C containment tank, which has been designed to use methanol to supply power to onboard hotel systems. “Working with Sanlorenzo on this innovative project affirms Lloyd’s Register’s role as a trusted advisor to our clients, and demonstrates our support for first movers developing solutions to reduce carbon emissions in the yachting sector,” said Paolo Izzo, Lloyd’s Register’s Italy, Monaco & Malta Sales & Marketing Manager, after presenting the approval certificate to Sanlorenzo during the 2023 Monaco Yacht Show in September.

Added Massimo Perotti, Sanlorenzo’s Executive Chairman and CEO, “Sanlorenzo is a trailblazer on the path to carbon neutrality in the yachting world: through the relentless work of our R&D department, we continue to take revolutionary steps in introducing technological systems aimed at reducing the environmental impact of yachts.”

These projects are perfect examples of how the superyacht industry – spurred on by willing clients – is embracing change, but there’s more to the story than that. It also demonstrates that superyachting – and those pioneering superyacht owners who are prepared to put their own money and their own yachting experiences on the line – are the proving ground for the wider marine industry, much like Formula 1 serves as the technical proving ground for automotive. “Project Cosmos is essentially a validation experiment,” Breman says. “We found this client who is willing to take this leap of faith with us.” Nefzi agrees, citing Feadship’s hydrogen project as a parallel owner experience. “We are all trying to experiment,” he explains, “and we found owners who are willing to experiment with us simply to bring the technology on further.”

50Steel by Sanlorenzo

50Steel by Sanlorenzo

For Stefano de Vivo, an engineer and Chief Commercial Officer at yachtbuilding giant Ferretti Group, this is the crux of the matter – it’s not just about what these projects mean for yachting, but what they mean for commercial shipping and, in turn, what that means for massively reducing the environmental impact that commercial shipping has. “It’s the results which count, as in what we have to do to put methanol on board, and what are the emissions at the end,” he enthuses. “Shipping cannot take risks because when you’re building a commercial ship you’re thinking that you have 30 years to make money off it, you need three years to build it, you cannot have downtime and so on. So what luxury yachting is doing is we’re actually testing this technology – our clients want to be the ones to test stuff that others are still not using.”

On larger yachts, he cites, that means making a move to, for example, methanol as the main fuel, and on smaller yachts the development and implementation of advanced exhaust treatment systems that remove nitrous oxide and other harmful exhaust gases. “That’s another case where shipping didn’t do that – they weren’t going to take the risk because they didn’t know if they could keep engine room temperatures low enough and so on,” he explains.

“It’s already happened with exhaust treatment, because as an industry we are doing all this open source,” he concludes. “The luxury yachting sector is passing on that knowledge and those results to show that yes, it can be done, that these are the results and that you can do it in your maritime sector as well.”